This flooring (NON-PVC) PET flooring is an upgraded iterative product of PVC flooring. PET flooring continues to retain core advantages such as easy installation. It uses bottle flake granule and calcium carbonate powder as the main materials. It is more environmentally friendly than PVC flooring, and has better heat-resistant, stable performance, scratch-resistant and durable. Welcome new and regular customers from the international industry come to negotiate.

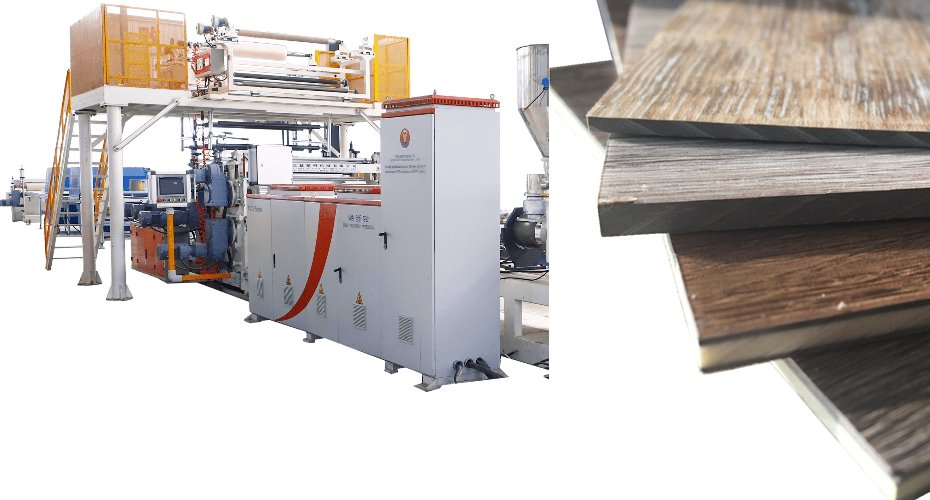

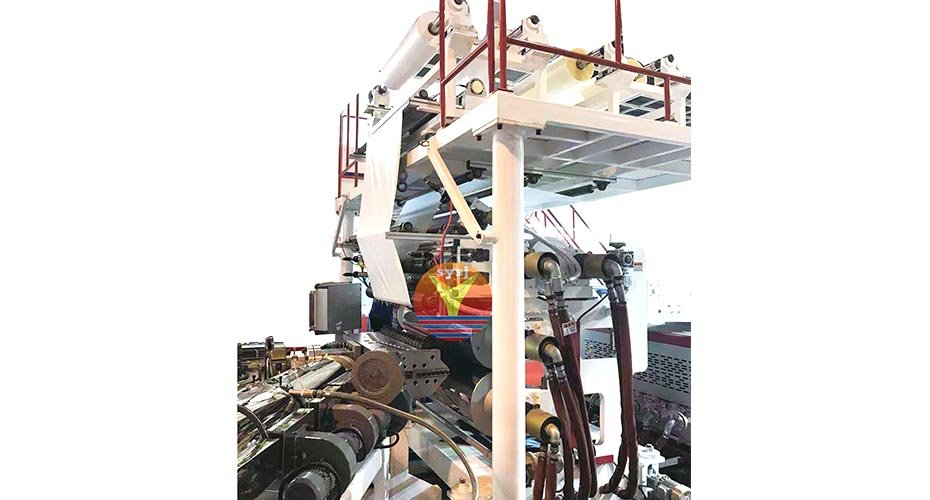

The Newest Plastic PVC Vinyl Flooring Wood Plastic Composite WPC Flooring Extruder Machine completely subverting the traditional processing mode that multi-step flooring film can be combined together by multi-step method which has caused great sensation in the floor circle.

The whole process does not use glue, paint and other substances containing formaldehyde and toluene. The materials used are non-toxic formaldehyde free, waterproof sterilization, convenient installation, realistic lines, super wear-resistant waterproof, flame retardant and heat resistant

a.zero benzene and formaldehyde,no glue and poisonous substance,and it can be 100%recycled;b.stable perforance: no cracking, no expansion, no deformation, no maintenance and maintenance, easy to clean, save the cost of later maintenance and repair. c.Water proof and moisture proof. it can be used in an environment where traditional wood products cannot be applied;d.fire retardant: fire rating B1 level;e.anti-insect,termite-proof,antibacterial new flooring;f.good sound absorption effect:upto 20dB which is suitable for places such as: hospital,library;